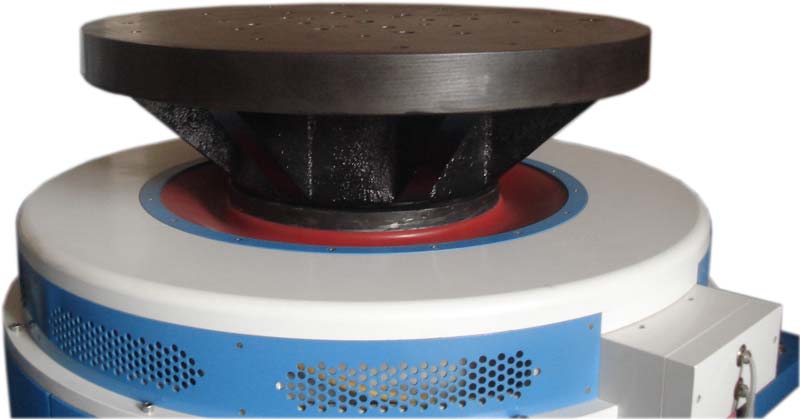

We are a renowned Manufacturer and Supplier of Head Expanders in India. We offer Head Expanders for applications where larger vertical test mounting surfaces are required. Head Expanders are manufactured from lightweight magnesium alloy, providing high strength-to-weight ratio. A choice of less expensive aluminum alloy is also available for smaller fixtures. The Head Expanders allows multiple items to be tested at the same time, decreasing total test cycle time. Head Expanders with load support guidance allow payloads with large footprints to be safely mounted and tested on the shaker, reducing the risk of damage to the shaker suspension system.

The Guided Head Expanders are designed for testing of large, heavy packages to handle tough transportation and other demanding test profiles while providing additional restraints and load support.

Customized fixtures can also be designed and manufactured based on the customer’s specimen mounting requirement. Cube, L type and T type fixtures for testing of multiple small sized components are available. The customized cube, L or T types are preferred by customers for three axis testing without investing in an additional slip table.

The head expanders are designed and fabricated as bolt-on platform for shaker armature to accommodate large size objects during vertical axis vibration testing (Z-axis). In most of the applications, the space on armature top of shaker is a constraint for mounting large fixture and test objects and in such cases an head expander plays a crucial role. The head expanders are made of Al/ Mg alloy material having casted/ welded structure in circular or square shape to suit different test requirements. For voluminous and overhanging objects, the guided head expanders (Load Support Platform) are preferred which enhances the loading capacity and restricts overturning moments during vibration testing thus safeguarding the armature assembly as well.

These equipment are designed to cater wide range of vibration testing and analysis such as design qualification, product reliability and environmental stress screening. The heavy steel structure body and mechanical linkages are made of high quality materials to make it suitable for longer service life. The machine is supported on air springs to isolate the vibration to be transferred to the ground thus eliminates the requirement of special foundation and can be installed on any standard industrial floor.

| Shaker Model | Head Expander Circular | Head Expander Square | ||||||

|---|---|---|---|---|---|---|---|---|

| Model | Top Surface Dia(mm) |

Insert Pattern (mm) |

Mass (kg) |

Model | Size(mm) | Insert Pattern (mm) |

Mass (kg) |

|

| DS140 | DCHE-30 DCHE-40 |

300*400 | 50×50 50×50 |

12 21 |

DSHE-30 DSHE-40 |

300*400 | 50×50 50×50 |

13 23 |

| DS180 | DCHE-40 DCHE-60 |

300*400 | 50×50 50×50 |

12 21 |

DSHE-40 DSHE-60 |

300*400 | 50×50 50×50 |

13 23 |

| DS240 | DCHE-40 DCHE-60 |

400*600 | 50×50 100×100 |

23 36 |

DSHE-40 DSHE-60 |

400*500 | 50×50 100×100 |

26 40 |

| DS300 | DCHE-60 DCHE-80 |

600*800 | 100×100 100×100 |

37 85 |

DSHE-60 DSHE-80 |

600*800 | 100×100 100×100 |

41 95 |

| DS360 | DCHE-60 DCHE-80 DCHE-100 |

600*800*1000 | 100×100 100×100 100×100 |

38 90 145 |

DSHE-60 DSHE-80 DSHE-100 |

600*800*1000 | 100×100 100×100 4100×100 |

42 100 160 |

| DS440 | DCHE-80 DCHE-100 |

800*1000 | 100×100 100×100 100×100 |

95 155 |

DSHE-80 DSHE-100 |

800*1000 | 100×100 100×100 100×100 |

105 170 |

- Above specifications are standard specifications, subject to revision due to continuous Improvement/ developmental activities

without notice. However, the specifications quoted by us in a proposal always supersede the printed/ published specifications. - Customized testing solutions and spectfications are provided on demand.